Join the Blanchard Team..

Apply Now

Construction sites depend on reliable machines to get jobs done quickly and effectively. Picking the right equipment helps control costs and project timelines while supporting your business. Skid steers and compact track loaders (CTLs) are two popular and similar-looking pieces of construction equipment. They both use front-mounted attachments, fit into tight spaces and provide versatile support.

However, the difference in their movement can significantly impact your jobsite. If you’re trying to decide on the right investment for your business, it comes down to where and how you plan to work. Let’s compare skid steers versus compact track loaders and see where each works best.

A skid steer is a wheeled compact loader. It’s lightweight, easy to transport and maneuverable. It features front attachments and multiple large wheels, so it can easily turn in tight spaces. Construction projects can use skid steers for loading, lifting, sweeping, trenching and snow removal.

Skid steers’ wheels give them excellent traction and maneuverability on solid surfaces like concrete and asphalt. They’re practical, fast and low-maintenance, saving your team time and money.

A CTL is a compact loader with tracks instead of wheels. The track system distributes a CTL’s weight across a wider surface area, providing better traction and lower ground pressure. CTLs are built to move across soft, muddy or uneven ground without slipping. Tracks also offer more stability when lifting heavy materials, but they require more upkeep and replacements than standard wheels.

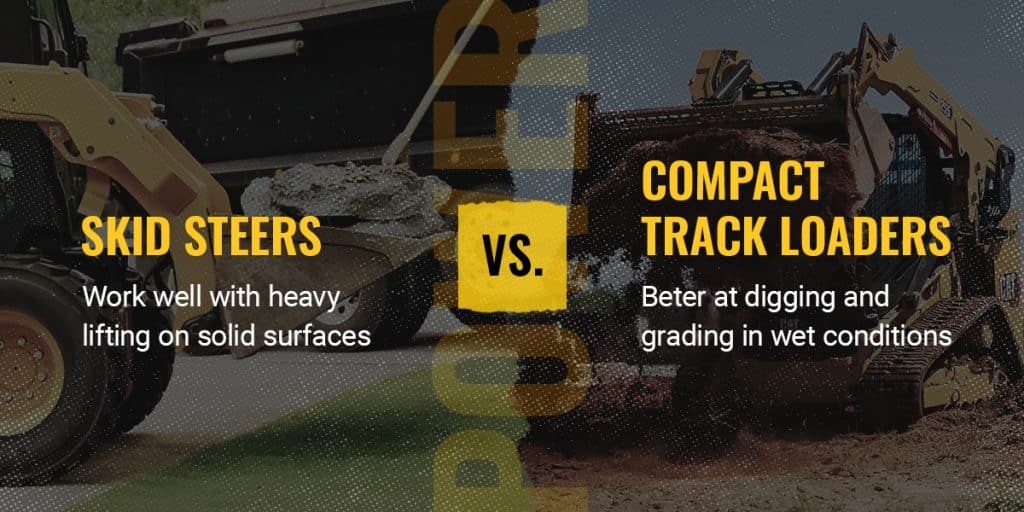

Compact track loaders have tracks, while skid steers have wheels. Both types of equipment have front attachments for loading, lifting, digging and hauling. However, their different movement designs make them suited for unique terrain.

While skid steers and CTLs have similar core functions, there are several key distinctions. Construction operations must understand how each machine performs in specific conditions to ensure they invest in the best machine for their long-term needs. Let’s break down terrain, speed, power and other features.

Terrain is one of the most important factors in choosing between a skid steer and a CTL. Skid steers have four wheels, which makes them ideal for hard, even surfaces. You’ll get a faster, smoother ride on concrete, packed gravel and asphalt.

CTLs are better on soft or unstable terrain. Tracks distribute weight more evenly, preventing CTLs from sinking into mud, sand or loose soil. They also get better traction on slopes and slippery surfaces. If you’re working on new ground, CTLs offer better stability and control.

Skid steers are known for their agility. Their wheels make them lighter and faster across solid ground than CTLs. Skid steers can pivot tightly, making them an excellent choice for urban spaces or indoor work. Operators have an easier time working on narrow jobsites with skid steers.

CTLs can also make tight turns, but their added track weight and design make them much slower than skid steers. However, slower speeds make CTLs smoother and give them more traction on uneven or soft ground. Skid steers are more maneuverable, but CTLs hold up better on rough terrain.

Skid steers and CTLs can run many of the same attachments. However, CTLs have more pushing power and stability. They also have a lower center of gravity and weigh more, which gives them an edge over skid steers when it comes to traction and lifting heavy loads.

Skid steers are more affected by slippery or loose surfaces. They work well with heavy lifting on solid surfaces, but digging and grading in wet conditions are better handled by CTLs.

Standard skid steers are usually less expensive up front. They’re easier to transport, maintain and fuel. Teams can inspect and replace their tires faster. If you want more cost-effective, lower-maintenance equipment, consider a skid steer.

CTLs are more expensive and require extra upkeep. Tracks wear out faster on hard surfaces, and their undercarriages are harder to clean out. Plus, repairing or replacing tracks costs more than replacing wheels. That being said, CTLs earn their keep in more demanding environments.

Both skid steers and CTLs have versatile attachment options. Buckets, forks, augers, trenchers and other attachments are compatible with both. Switching attachments between these two types of equipment is common, as long as the coupler and hydraulic flow match.

However, the CTL’s extra traction and stability mean it’s better for high-horsepower or high-resistance attachments like mulchers or cold planers. A CTL might offer better performance for operations that use heavier tools frequently.

Skid steers are a good investment for jobs that involve solid, finished surfaces and tight maneuvering. Wheels offer faster travel and smoother turning if you’re working on concrete or other hard surfaces. Consider skid steers for the following applications:

Skid steers are also easier and less expensive to transport between sites. Lighter weight means lower trailer and fuel costs, plus fewer specialized hauling needs. These cost savings make skid steers great for owner-operators or small crews working small jobs across multiple locations.

Choose skid steers for:

CTLs thrive on rough terrain. A CTL offers better traction and control if you’re working on soft or wet ground or steep grades. Track loaders are also better for heavy-duty applications that need more stability and power. When lifting heavy materials or running high-torque attachments, tracks reduce slippage. Use compact track loaders for projects like:

While CTLs are more expensive to purchase and maintain, they can handle more difficult work than skid steers. Choose CTLs for:

Whether you’re leaning toward a skid steer or a CTL, Blanchard Machinery Company can help. We have the equipment and expertise to help you make the best choice for your business. We carry the full line of new Cat® compact equipment, built for power, precision and productivity, in South Carolina. With over 40 years of industry experience, you can count on us to give you reliable advice and lasting support for all your equipment needs.

Need help deciding? Our team will walk you through your options. We offer approved equipment attachments, repair and parts services, and financing plans to fit your budget. Visit your nearest Blanchard Machinery Company location, and let’s get to work.