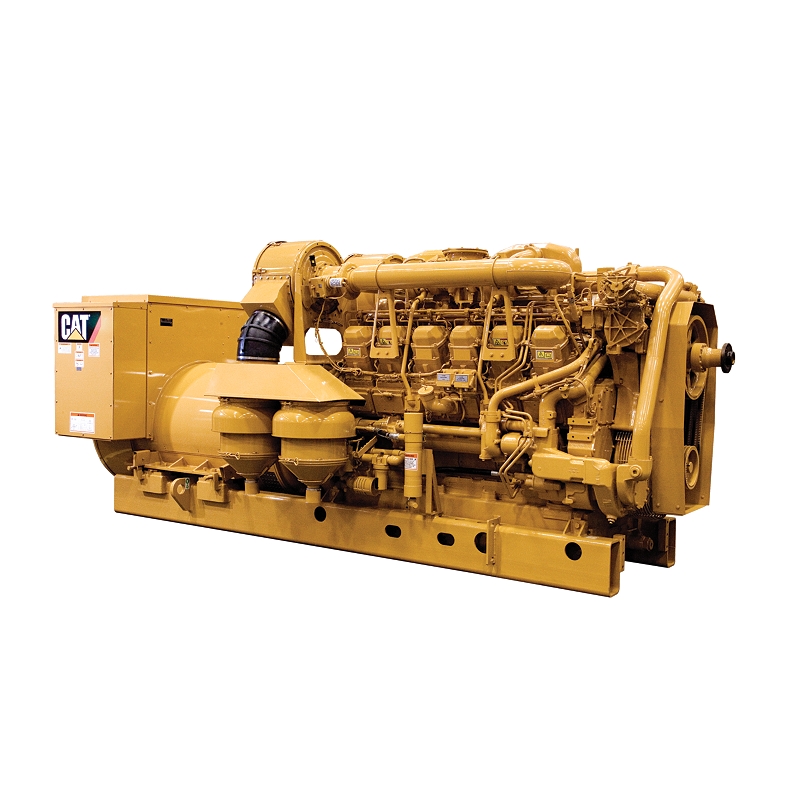

Maximum Rating1800BHP

EmissionsNon-certified

Displacement3158in³

Minimum Rating1020BHP

Bore6.69in

Stroke7.48in

Rated Speed1800r/min

AspirationTurbocharged-Aftercooled

Governor and ProtectionW3161

Engine Weight - Net Dry11462lb

Rotation from Flywheel EndCounterclockwise

Oil Change Interval500

Flywheel and Flywheel HousingSAE No. 00

Flywheel Teeth183

Minimum Cooling System - Engine Only41gal (US)

Length105.3in

Width67in

Height67.7in