Engine Power - ISO 14396:2002580hp

Engine ModelCat® C18

Rated Speed1700/rpm

Peak Power Speed1500/rpm

Gross Power - SAE J1995:2014588hp

Net Power - SAE J1349:2011538hp

Bore5.7in

Stroke7.2in

Displacement1105in³

Peak Torque - 1,200 rpm2104lbf·ft

Torque Rise58%

Note (1)Three engine emission options are available: 1. Meets U.S. EPA Tier 4 Final, EU Stage V, and Japan 2014 emission standards. 2. Meets Brazil MAR-1 emission standards, equivalent to U.S. EPA Tier 3 and EU Stage IIIA. 3. Meets China Nonroad Stage IV emissio

Note (2)Net power advertised is the power available at the flywheel when the engine is equipped with fan at minimum speed, air intake system, exhaust system, and alternator.

Operating Weight112574lb

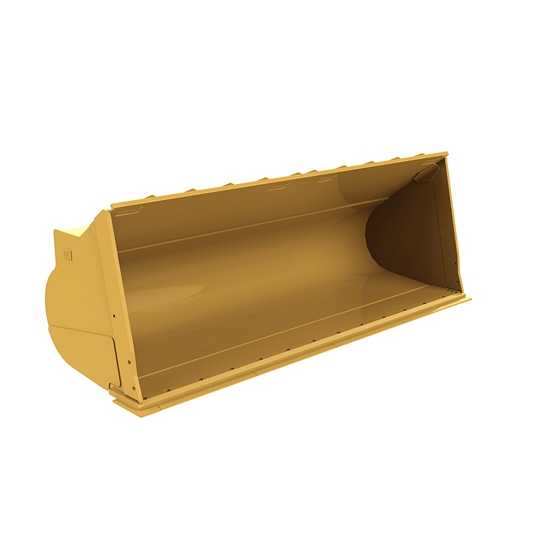

Bucket Capacity Range4.7-13 m3 (6.2-17 yd3)

Rated Payload - Quarry Face12.5t

Rated Payload - Loose Material16t

Cat Truck Match - Standard770 - 772

Cat Truck Match - High Lift773 - 775

Transmission TypeCat planetary powershift

Forward - 14mile/h

Forward - 27.2mile/h

Forward - 312.7mile/h

Forward - 421.6mile/h

Reverse - 14.7mile/h

Reverse - 28.3mile/h

Reverse - 314.4mile/h

Direct Drive - Forward 1Lock-up disabled

Direct Drive - Forward 27.8mile/h

Direct Drive - Forward 313.9mile/h

Direct Drive - Forward 424.4mile/h

Direct Drive - Reverse 15mile/h

Direct Drive - Reverse 28.9mile/h

Direct Drive - Reverse 315.8mile/h

Lift/Tilt System - CircuitEH- Positive Flow Control, Flow Sharing

Lift/Tilt System - PumpVariable displacement piston

Maximum Flow at 1,400-1,860 rpm153gpm

Relief Valve Setting - Lift/Tilt4757psi

Cylinders, Double Acting - Lift, Bore and Stroke210 mm × 1050 mm (8.7 in × 41.3 in)

Cylinders, Double Acting - Tilt, Bore and Stroke266 mm × 685 mm (8.7 in × 27 in)

Pilot SystemVariable displacement piston

Relief Valve Setting - Main551psi

Rack Back4.5s

Raise8s

Dump2.2s

Lower Float Down3.5s

Total Hydraulic Cycle Time - Empty Bucket18.2s

Steering System - CircuitPilot, load sensing

Steering System - PumpPiston, variable displacement

Maximum Flow at 1,400-1,600 rpm71.3gpm

Relief Valve Setting - Steering4351psi

Total Steering Angle86 °

Steering Cycle Times - High Idle3.4s

Steering Cycle Times - Low Idle5.6s

Air Conditioning• The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a or R1234yf. See the label or instruction manual for identification of the gas. • If equipped with R134a (Global Warming Potential = 1430), the system

FrontFixed

RearTrunnion

Oscillation Angle13 °

BrakesISO 3450:2011

ROPS/FOPSROPS/FOPS meet ISO 3471:2008 and ISO 3449:2005 Level II standards

Operator Sound Pressure Level (ISO 6396:2008)73dB(A)

Machine Sound Power Level (ISO 6395:2008)111dB(A)

Operator Sound Pressure Level (ISO 6396:2008)*72dB(A)

Machine Sound Power Level (ISO 6395:2008)**109dB(A)

Note (1)* For machines in European Union countries and in countries that adopt the “EU Directives” and “UK Directives.”

Note (2)** European Union Directive “2000/14/EC” as amended by “2005/88/EC” and UK Noise Regulation 2001 No. 1701.

Note (3)The machine sound power level was measured according to ISO 6395:2008. The measurement was conducted at 70% of the maximum engine cooling fan speed.

Note (4)The operator sound pressure level was measured according to ISO 6396:2008. The measurement was conducted at 70% of the maximum engine cooling fan speed.

Note (5)Hearing protection may be needed when the machine is operated with a cab that is not properly maintained or when the doors or windows are open for extended periods or in a noisy environment.

Operator Sound Pressure Level (ISO 6396:2008)73dB(A)

Machine Sound Power Level (ISO 6395:2008)112dB(A)

Operator Sound Pressure Level (ISO 6396:2008)*72dB(A)

Machine Sound Power Level (ISO 6395:2008)**110dB(A)

Note (1)* For machines in European Union countries and in countries that adopt the “EU Directives” and “UK Directives.”

Note (2)** European Union Directive “2000/14/EC” as amended by “2005/88/EC” and UK Noise Regulation 2001 No. 1701.

Note (3)The machine sound power level was measured according to ISO 6395:2008. The measurement was conducted at 70% of the maximum engine cooling fan speed.

Note (4)The operator sound pressure level was measured according to ISO 6396:2008. The measurement was conducted at 70% of the maximum engine cooling fan speed.

Note (5)Hearing protection may be needed when the machine is operated with a cab that is not properly maintained or when the doors or windows are open for extended periods or in a noisy environment.

Fuel Tank188gal (US)

Cooling System31.7gal (US)

Coolant (Validated by Test Cell Fill Quantities)33gal (US)

Crankcase15.9gal (US)

Diesel Exhaust Fluid Tank (For Tier 4 Final/Stage V Only)8.7gal (US)

Transmission24.3gal (US)

Transmission - Validated by Test Cell Fill Quantities29gal (US)

Differential - Final Drives - Front49.1gal (US)

Differential - Final Drives - Rear49.1gal (US)

Hydraulic System Factory Fill125.5gal (US)

Hydraulic System - Tank Only63.4gal (US)

Note• All non-road Tier 4 Final/Stage V diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels** up to: – 20% biodiesel FAME (fatty acid methyl ester

Ground to Top of ROPS13.8ft

Ground to Top of Exhaust Stacks14.8ft

Ground to Top of Hood10.9ft

Rear Axle - Centerline to Bumper10.5ft

Front Axle Centerline to Bucket Tip14ft

Wheel Base14.9ft

Maximum Overall Length39.3ft

Ground to Lower Hitch Clearance1.9ft

Clearance at Maximum Lift11.9ft

B-Pin Height - Maximum Lift18ft

Maximum Overall Height - Bucket Raised24.5ft

Reach - Maximum Lift6.5ft

Ground to Top of ROPS13.8ft

Ground to Top of Exhaust Stacks14.8ft

Ground to Top of Hood10.9ft

Rear Axle - Centerline to Bumper10.5ft

Front Axle Centerline to Bucket Tip15.3ft

Wheel Base14.9ft

Maximum Overall Length40.7ft

Ground to Lower Hitch Clearance1.9ft

Clearance at Maximum Lift13.3ft

B-Pin Height - Maximum Lift19.3ft

Maximum Overall Height - Bucket Raised25.8ft

Reach - Maximum Lift6.8ft