Maximum Gross Power74.7hp

Engine ModelCat C2.8*

Maximum Engine Speed2550 rpm

Maximum Gross Power - Rated Engine Speed2400r/min

Maximum Gross Power - SAE J199574.7hp

Maximum Gross Power - ISO 1439674.3hp

Maximum Gross Power - ISO 14396 (metric)75.3mhp

Rated Net Power - Rated Engine Speed2400r/min

Rated Net Power - SAE J134972.7hp

Rated Net Power - ISO 924972.1hp

Rated Net Power - 2,400 rpm - ISO 9249 (metric)73.1mhp

Maximum Gross Torque - SAE J1995222lb/ft

Maximum Gross Torque - ISO 14396221lb/ft

Maximum Net Torque - SAE J1349218lb/ft

Maximum Net Torque - ISO 9249217lb/ft

Displacement171in³

Bore3.54in

Stroke4.33in

Note*Meets U.S. EPA Tier 4 Final and EU Stage V emission standards.

Note (1)Advertised power is tested per the specified standard in effect at the time of manufacture.

Note (2)Net power advertised is the power available at the flywheel.

Note (3)#Maximum gross and net torque measured at 1,600 rpm.

Operating Weight12765lb

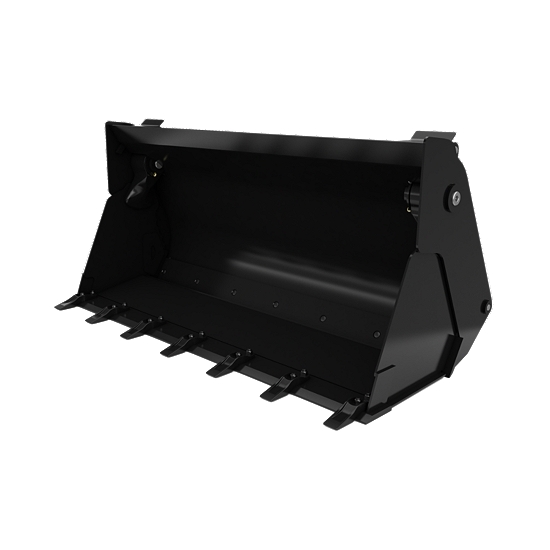

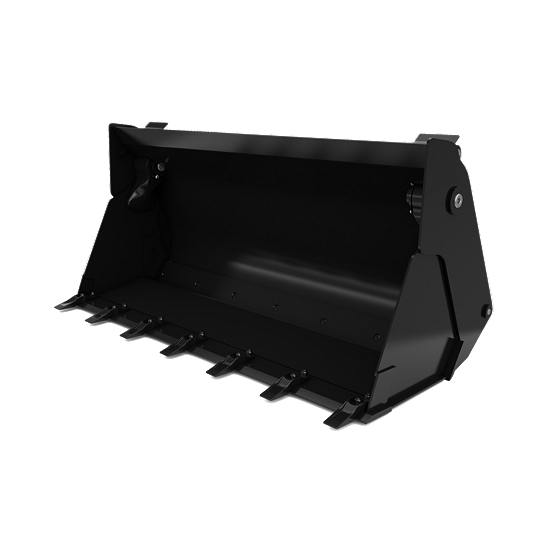

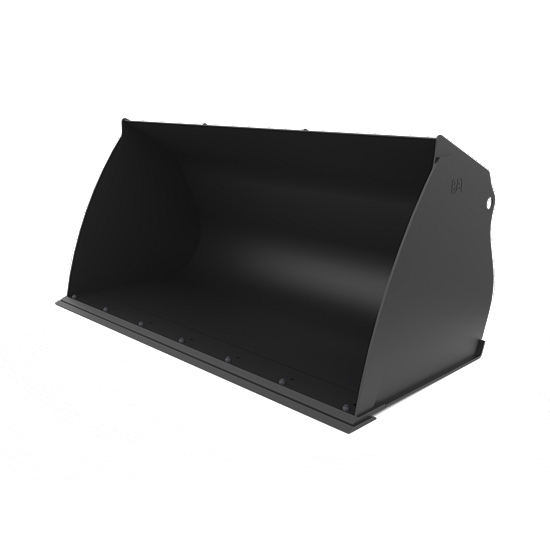

Bucket Capacities0.75-1.55 m³ (1.0-2.0 yd³)

Bucket Capacities - General Purpose0.80-1.35 m³ (1.0-1.7 yd³)

Bucket Capacities - Light Material1.25-1.55 m³ (1.6-2.0 yd³)

Multi-Purpose0.75-1.1 m³ (1.0-1.4 yd³)

NoteBucket selection must be made with an understanding of the material density and application to ensure machine stability is maintained within the tipping loads stated per model and configuration.

Note (1)Bucket capacities stated include BOCE, in line with ISO 7546.

Recyclability93%

Fuel Tank24Gal

Cooling System3.2Gal

Engine Crankcase2.3Gal

Axles - Front Center Differential2.3Gal

Axles - Rear Center Differential2.3Gal

Hydraulic System - Including Tank17.8Gal

Hydraulic Tank11.8Gal

Transmission0.6Gal

NoteNo Diesel Exhaust Fluid (DEF) fluid needed on this size engine.

FrontFixed (standard), Locking Differential (optional)

RearFixed (standard), Locking Differential (optional)

NoteOscillation of ±11 degrees via hitch between front and rear frames.

Steering Articulation Angle - Each Direction39°

Maximum Flow - Steering Pump12.3gpm

Maximum Working Pressure - Steering Pump3336psi

Steering Cycle Times – (full left to full right) – at High Idle2.8s

Number of Steering Wheel Turns - Full Left to Full Right or Full Right to Full Left3.25 turns or 4.00 turns

Forward and Reverse - Speed Range Creep#6mile/h

Forward and Reverse - Speed Range 1*6mile/h

Forward and Reverse - Speed Range 2** - High Speed10.5mile/h

Forward and Reverse - Speed Range 2** - Standard12mile/h

Forward and Reverse - Speed Range 3***25mile/h

Note#Factory default shown, can be adjusted to any speed up to 19 km/h (12 mph).

Note (1)*Creep function not available in this gear or above.

Note (2)**Max speed dependent on model and configuration (standard vs. high speed transmission).

Note (3)***Reverse is 30 km/h (19 mph).

Tire Size - Standard*405/70 R18 SPT9

Tire Size - Optional405/70 R18 Powerloads

Tire Size - Optional (1)340/80 R18 XMCL/Bibload

Tire Size - Optional (2)340/80 R18 TRI 2

Tire Size - Optional (3)40X14-20 TL, SM/TR

Tire Size - Optional 4340/80 R18 Duraforce

Note*This tire has been used for all dimension, stability and performance data.

Note (1)Other tire choices are available. Contact your Cat dealer for details.

Note (2)Caterpillar recommends that you consult a tire supplier to evaluate all conditions before selecting a tire model.

ROPSISO 3471:2008

FOPSISO 3449:2005 Level II

Note (1)Canopy and cab, Rollover Protective Structures (ROPS) are available worldwide. Canopy not available in EU.

Note (2)The declared dynamic operator sound pressure levels per ISO 6396:2008*, when properly installed and maintained, is 71 dB(A).

Note (3)*Measurements were conducted with the cab doors and windows closed.

Note (4)The labelled sound power level for the CE marked configurations when measured according to the test procedure and conditions specified in 2000/14/EC is 101 dB(A). 99 dB(A) Low Sound – Option available.

Main Relief - 1st Auxiliary (3rd slice)3408psi

Main Relief - 1st Auxiliary (3rd slice) - Standard Flow*21gpm

Main Relief - 1st Auxiliary (3rd slice) - High Flow*32gpm

Main Relief - 2nd Auxiliary (4th slice)3408psi

Main Relief - 2nd Auxiliary (4th slice) - Flow12gpm

Hydraulic Cycle Time - Rackback2.2s

Hydraulic Cycle Time - Lift5s

Hydraulic Cycle Time - Dump1.6s

Hydraulic Cycle Time - Float Down2.8s

Note* Maximum flow stated, actual flow delta could be 6% from data shown. Also adjustable from 20% to 100% of maximum flow through display.

Height: Ground to Cab**8.5ft

Height: Ground to Beacon**9.08ft

Height: Ground Axle Center**1.58ft

Height: Ground Clearance**1ft

Length: Overall*17.58ft

Length: Rear Axle to Bumper4.58ft

Length: Hitch to Front Axle3.58ft

Length: Wheel Base7.08ft

Length: Front Axle to Front of Coupler3.5ft

Clearance: Bucket at 45° *8.25ft

Clearance: Load over Height**9.5ft

Clearance: Level Bucket**9.92ft

Height: Bucket Pin**10.67ft

Height: Overall**13.5ft

Reach: Bucket at 45° *2.33ft

Carry Height: Bucket Pin1.08ft

Dig Depth**0.33in

Width: Bucket6.75ft

Width: Tread Center4.67ft

Turning Radius: Over Bucket14.75ft

Width: Over Tires6.07ft

Turning Radius: Outside of Tires12.92ft

Turning Radius: Inside of Tires6.75ft

Rack Angle at Full Lift56°

Dump Angle at Full Lift45°

Rack Angle at Carry51°

Departure Angle - Degrees30°

Articulation Angle - Degrees39°

Operating Weight: Bucket ^12689lb

Tipping Load - Straight - ISO 14397-1 †9773lb

Tipping Load - Full Turn - ISO 14397-1 †8235lb

Operating Weight: Carriage and Tines ^^12220lb

Tipping Load - Straight †7807lb

Tipping Load - Full Turn †6569lb

80% of Tip: Firm and Level EN474-3 ††5255lb

Note (1)*Vary with bucket

Note (2)**Vary with tire

Note (3)^Horizontal Pin Lock Coupler (HPL-V) or Vertical Pin Coupler (SSL),1.05 m3 (1.4 yd3) general purpose bucket.

Note (4)^^Horizontal Pin Lock Coupler (HPL-V) or Vertical Pin Coupler (SSL), class II carriage, 1220 mm (4 ft) tines (500 mm [20 in] load center).

Note (5)†Full compliance to ISO 14397-1 (2007) Sections 1 thru 6 (fork 500 mm [20 in] load center), which requires 2% verification between calculation and testing.

Note (6)††Full compliance to EN474-3 and SAE J1197.

Note (7)#HPL-A weight, tipping and rated loads are within 1% of the HPL-V.

Note (8)Dimensions listed are for a machine configured with standard cab, heater, 20 km/h (12 mph), standard guarding, 80 kg (176 lb) operator, full fluids, SPT9 405/70 R18 tires and 1.05 m3 (1.4 yd3) general purpose bucket with bolt-on cutting edge or a class II

Note (9)Note: Goodyear POWERLOAD® tires can add up to approximately 140 kg (305 lb) to the full turn tip load and reduce vertical height by approximately 25 mm (1 in) compared to SPT9.

Height - Ground to Cab8.5ft

Height: Ground to Beacon**9.08ft

Height: Ground Axle Center**1.58ft

Height - Ground Clearance1ft

Length - Overall with Bucket18.17ft

Length: Rear Axle to Bumper4.58ft

Length: Hitch to Front Axle3.58ft

Length - Wheel Base7.08ft

Length: Front Axle to Front of Coupler4.33ft

Clearance - Bucket at 45°7.83ft

Clearance: Load over Height**9.5ft

Clearance - Level Bucket9.92ft

Height - Bucket Pin10.67ft

Height: Overall**13.83ft

Reach - Bucket at 45°2.67ft

Carry Height: Bucket Pin1.17ft

Dig Depth3in

Width - Bucket6.75ft

Width - Tread Center4.67ft

Turning Radius - Over Bucket15ft

Width - Over Tires6.08ft

Turning Radius: Outside of Tires12.92ft

Turning Radius - Inside Tire6.75ft

Rack Angle at Full Lift51°

Dump Angle at Full Lift50°

Rack Angle at Carry46°

Departure Angle - Degrees30°

Articulation Angle - Degrees39°

Operating Weight: Bucket ^12897lb

Tipping Load – Straight – ISO 14397-1 †8653lb

Tipping Load – Full Turn – ISO 14397-1 †7257lb

Operating Weight: Carriage and Tines ^^12414lb

Tipping Load - Straight †7416lb

Tipping Load - Full Turn †6266lb

80% of Tip: Firm and Level EN474-3 ††5013lb

Note (1)*Vary with bucket

Note (2)**Vary with tire

Note (3)^Horizontal Pin Lock Coupler (HPL-V) or Vertical Pin Coupler (SSL),1.05 m3 (1.4 yd3) general purpose bucket.

Note (4)^^Horizontal Pin Lock Coupler (HPL-V) or Vertical Pin Coupler (SSL), class II carriage, 1220 mm (4 ft) tines (500 mm [20 in] load center).

Note (5)†Full compliance to ISO 14397-1 (2007) Sections 1 thru 6 (fork 500 mm [20 in] load center), which requires 2% verification between calculation and testing.

Note (6)††Full compliance to EN474-3 and SAE J1197.

Note (7)#HPL-A weight, tipping and rated loads are within 1% of the HPL-V.

Note (8)Dimensions listed are for a machine configured with standard cab, heater, 20 km/h (12 mph), standard guarding, 80 kg (176 lb) operator, full fluids, SPT9 405/70 R18 tires and 1.05 m3 (1.4 yd3) general purpose bucket with bolt-on cutting edge or a class II

Note (9)Note: Goodyear POWERLOAD® tires can add up to approximately 140 kg (305 lb) to the full turn tip load and reduce vertical height by approximately 25 mm (1 in) compared to SPT9.