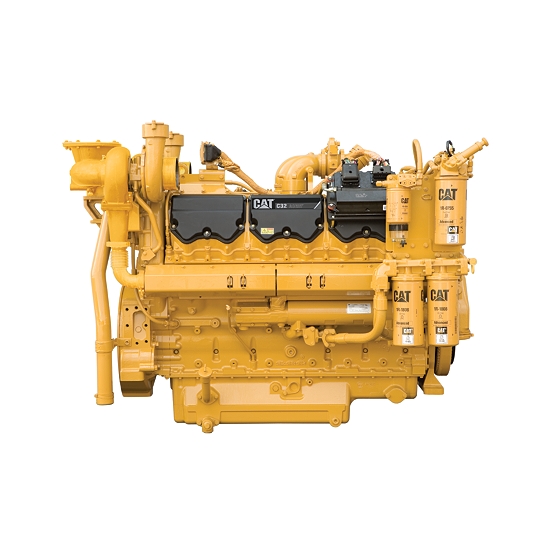

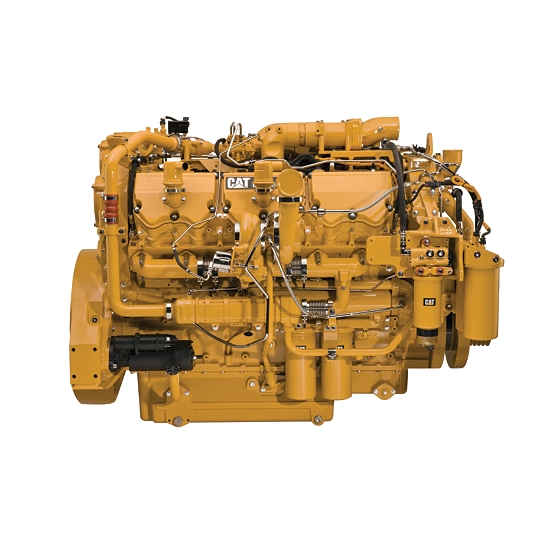

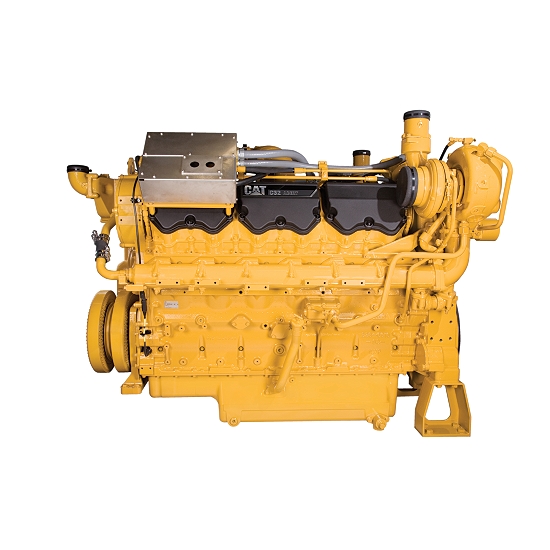

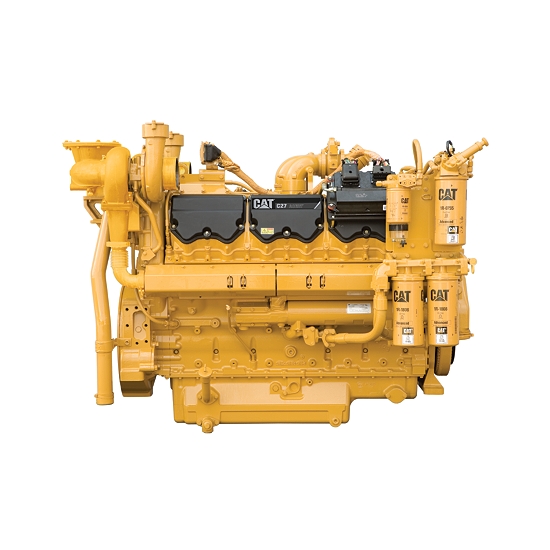

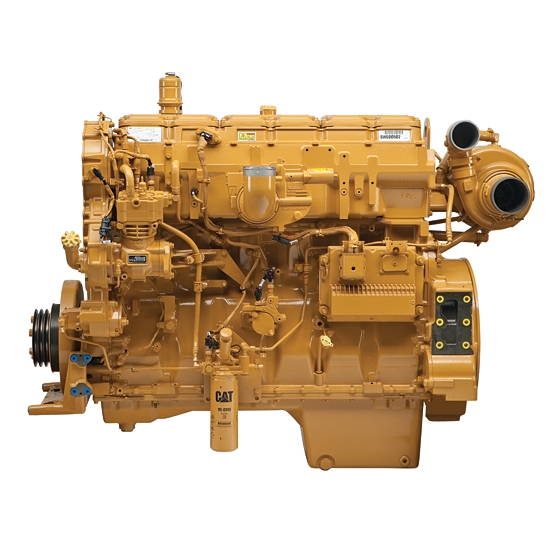

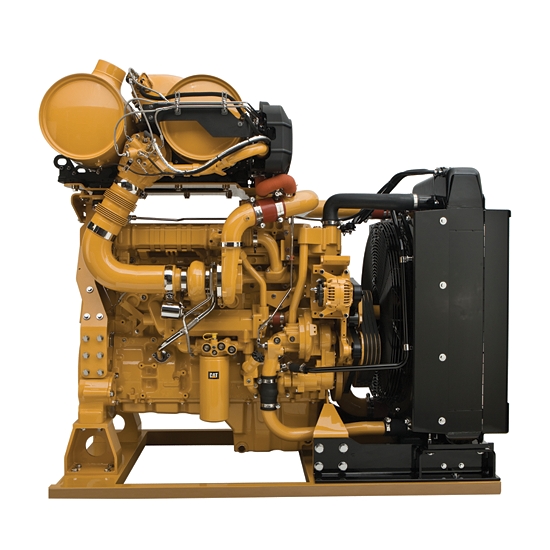

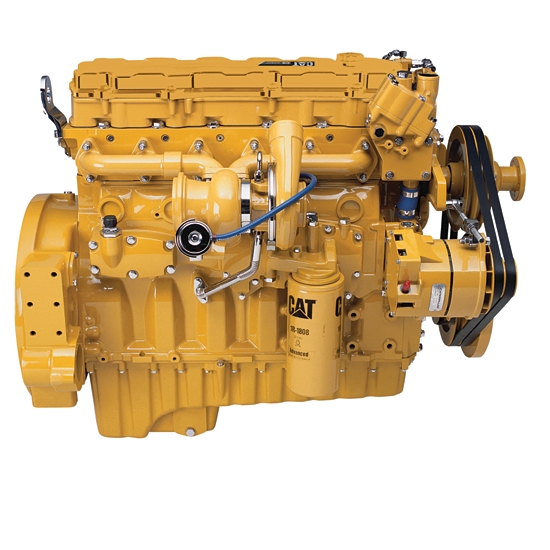

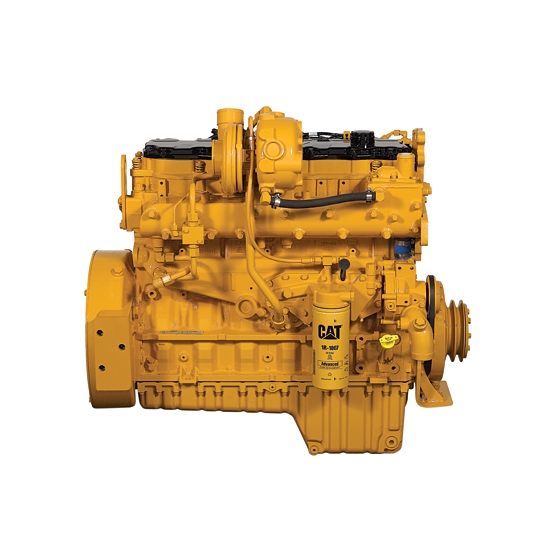

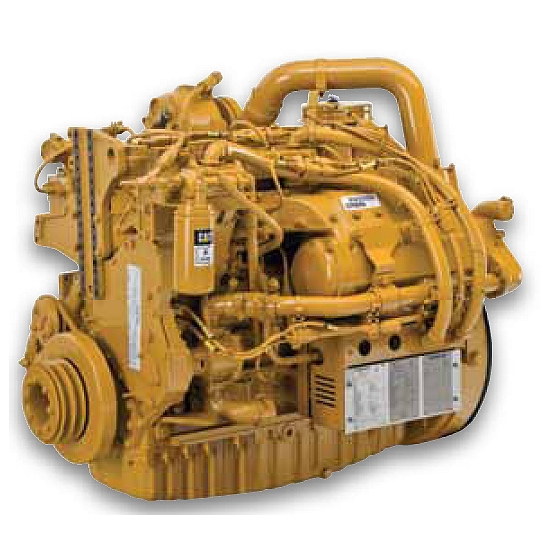

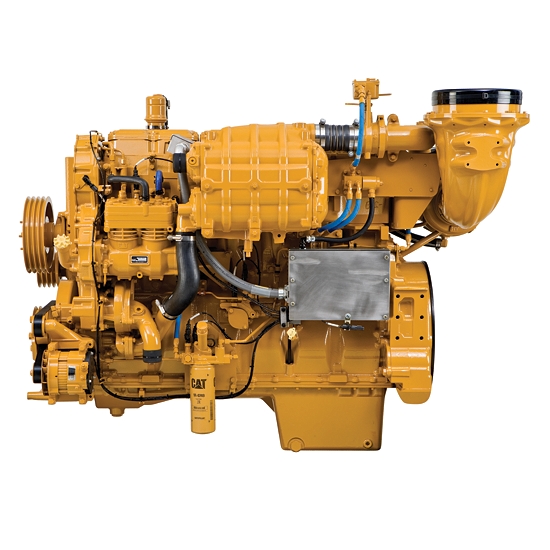

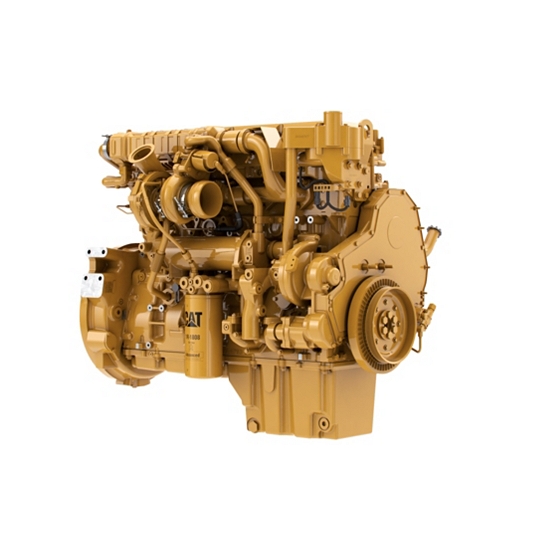

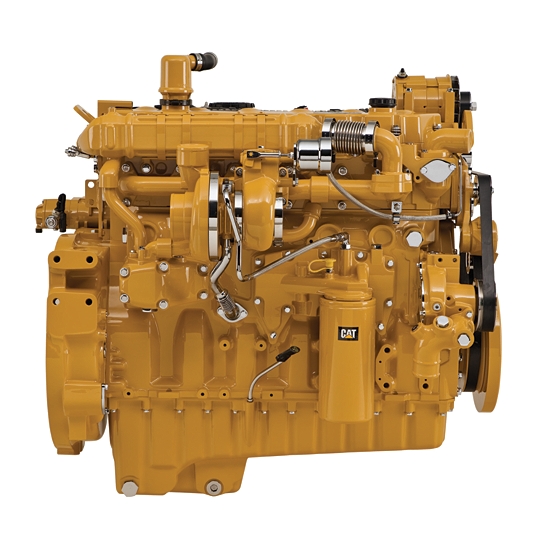

Maximum Rating520BHP

Displacement760in³

Minimum Rating385BHP

Governor and ProtectionElectronic (ADEM™ A3)

RPM2100r/min

AspirationTurbocharged-Aftercooled

Flywheel and Flywheel HousingSAE 1

Flywheel Teeth113

Rotation from Flywheel EndCounterclockwise

Stroke6.2in

Bore5.1in

EmissionsEPA and CARB Non-Road Mobile Tier 3, EU Stage IIIA

Length47.3in

Width39.9in

Height46.7in

Weight1976lb

Lube Oil System - Refill9gal (US)

Cooling System3.8gal (US)