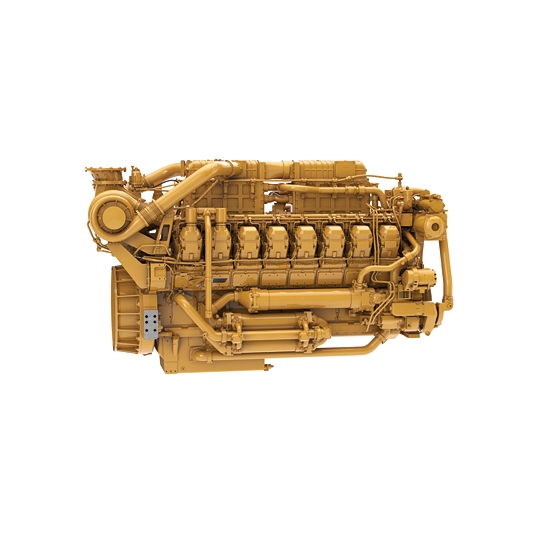

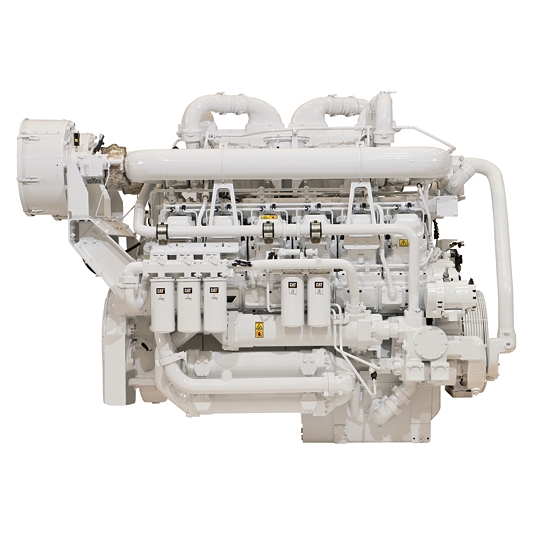

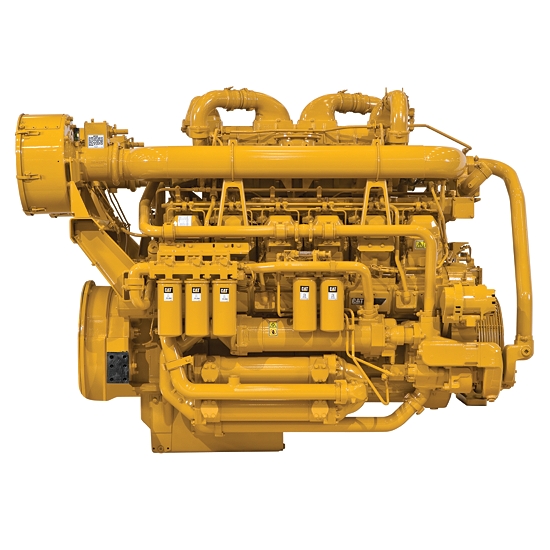

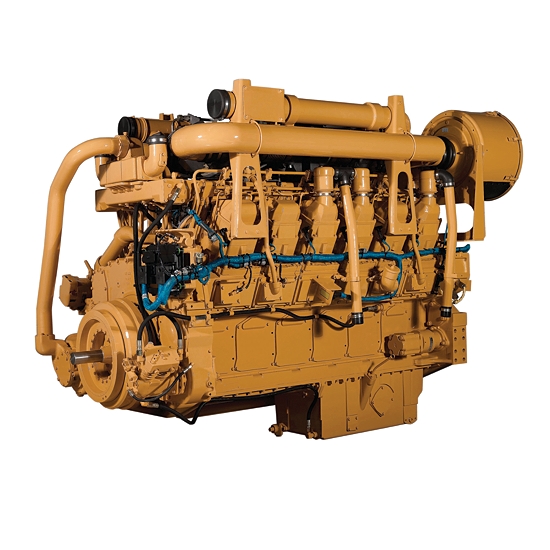

Maximum Rating2500BHP

Displacement3596in³

Minimum Rating2250BHP

AspirationTurbocharged-Aftercooled

Flywheel and Flywheel HousingSAE No. 0

Flywheel Teeth151

Stroke8.5in

Bore6.7in

EmissionsNon-Road Mobile EPA Tier 4 Final

Length123in

Width90.9in

Height104in

Weight15793lb